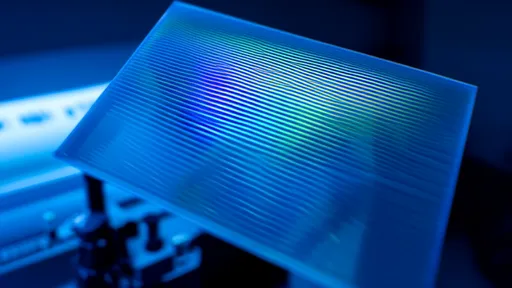

The science behind blue light filtering coatings has advanced significantly in recent years, with refractive index playing a crucial role in determining their effectiveness. As digital devices become ubiquitous in our daily lives, understanding how these protective films work at an optical level provides valuable insight for consumers and professionals alike.

At its core, the refractive index of a material describes how light propagates through it compared to a vacuum. For blue light filters, this property determines how effectively the coating can selectively block or absorb harmful high-energy visible (HEV) light while maintaining visual clarity. Manufacturers carefully engineer these thin-film coatings to have specific refractive indices that target the 415-455nm wavelength range where blue light is most potentially damaging.

The relationship between refractive index and blue light filtration isn't linear - it involves complex optical interference effects. When light hits the coating surface, some reflects while the rest transmits through multiple layers. By carefully controlling the refractive indices and thicknesses of these layers, manufacturers can create destructive interference specifically for blue wavelengths. This means blue light waves cancel each other out through phase manipulation while other colors pass through relatively undisturbed.

Modern blue light filters typically employ multilayer designs with alternating high and low refractive index materials. The high-index layers (often metal oxides like titanium dioxide with n≈2.4-2.7) provide strong light interaction, while the low-index layers (commonly silicon dioxide or magnesium fluoride with n≈1.38-1.7) create the necessary optical contrast. This combination allows precise wavelength selection through constructive and destructive interference effects.

Material science breakthroughs have enabled more sophisticated refractive index engineering. Recent developments include gradient-index coatings where the refractive index gradually changes across layers rather than abrupt transitions. These advanced designs can provide broader spectral control with smoother transitions between filtered and transmitted wavelengths, reducing the yellowish tint that plagued earlier blue light filters.

The measurement of refractive index in blue light coatings presents unique challenges. Standard refractometers designed for bulk materials often prove inadequate for thin-film applications. Instead, manufacturers rely on spectroscopic ellipsometry - a technique that analyzes how polarized light reflects off the coating at various angles. This provides detailed information about both refractive index and thickness for each layer in the stack.

Environmental factors can influence the refractive index of blue light filters over time. Humidity, temperature fluctuations, and UV exposure may cause subtle changes in the coating's optical properties. High-quality filters incorporate protective top layers that stabilize the refractive indices of underlying functional layers. Accelerated aging tests help manufacturers predict how these values might shift throughout the product's lifespan.

Consumer misconceptions about refractive index abound in the blue light filter market. Some assume higher refractive index always correlates with better protection, when in reality the relationship is more nuanced. An optimal blue light filter balances refractive index with proper layer thickness and sequence to target specific wavelengths without compromising color accuracy or introducing unwanted visual artifacts.

The military and aerospace industries have driven much of the advanced refractive index engineering now found in consumer blue light filters. Applications like helmet visors for fighter pilots and protective lenses for spacecraft windows require extreme precision in optical filtering. These demanding environments necessitated the development of coatings that could maintain consistent refractive properties under intense radiation and temperature variations.

Future developments in blue light filter technology may incorporate metamaterials - artificially engineered structures with refractive indices not found in nature. These could enable negative refraction or other exotic optical effects for more selective filtering. Researchers are also exploring liquid crystal-based filters where the refractive index can be electrically tuned for adjustable protection levels throughout the day.

From an optical physics perspective, the refractive index tells only part of the blue light filtration story. The absorption coefficient, dispersion relations, and nonlinear optical properties all contribute to a coating's overall performance. However, refractive index remains the foundational parameter that enables precise wavelength selection through interference effects.

As display technologies evolve with higher brightness and wider color gamuts, blue light filters must adapt their refractive index profiles accordingly. The latest OLED and microLED displays emit light at slightly different blue wavelengths than traditional LCDs, requiring coating adjustments. This constant technological arms race ensures refractive index engineering remains an active area of research and development.

The business implications of refractive index optimization are significant. Premium blue light filters command higher prices based on their advanced optical designs, with refractive index control being a key differentiator. Manufacturers guard their specific layer recipes and deposition techniques as valuable trade secrets, as small refractive index variations can substantially impact product performance.

Independent testing has revealed wide variations in refractive index quality among commercial blue light filters. Some budget products use simplified single-layer designs that provide minimal wavelength selectivity, while others employ sophisticated multilayer stacks with carefully tuned refractive indices. This performance gap explains the dramatic price differences in the market.

For eyecare professionals, understanding refractive index principles helps in recommending appropriate blue light solutions. Patients with particular visual needs or sensitivities may benefit from filters with specific refractive index profiles. This technical knowledge enables practitioners to move beyond marketing claims and evaluate products based on their actual optical properties.

The standardization of refractive index measurement for blue light filters remains an ongoing challenge. Without industry-wide testing protocols, comparing products from different manufacturers proves difficult. Various organizations are working to establish benchmarks that account for refractive index characteristics under real-world usage conditions.

Looking ahead, the intersection of refractive index engineering and artificial intelligence promises to accelerate blue light filter development. Machine learning algorithms can simulate countless layer combinations to identify optimal refractive index sequences that would be impractical to discover through traditional experimentation alone. This computational approach may lead to breakthrough designs in the coming years.

Ultimately, refractive index serves as the invisible hand guiding blue light filtration performance. While consumers may never see or directly measure this property, its careful manipulation enables the protective benefits that make modern digital life more sustainable for our eyes. As research continues, we can expect even more sophisticated applications of refractive index science in visual health technologies.

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025